You’ve probably seen it in movies, postcards, or even in person—the Golden Gate Bridge. But have you ever wondered what it took to build this iconic structure? The challenges of building the Golden Gate Bridge were as massive as the bridge itself. It wasn’t just about engineering; it was about overcoming nature, human limitations, and financial constraints.

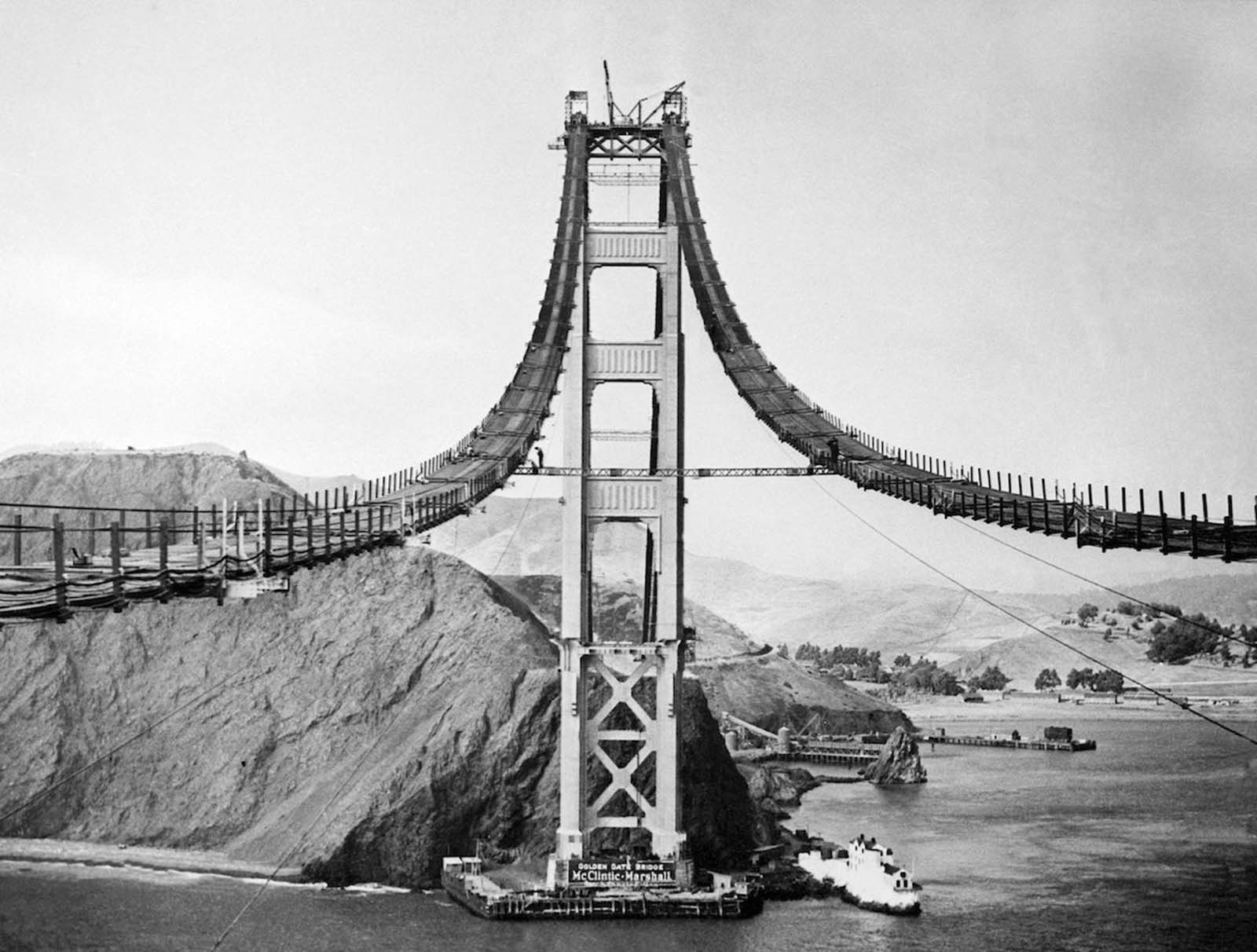

This isn’t just any bridge—it’s a symbol of human ingenuity and perseverance. When construction began in the early 1930s, no one knew whether it would even be possible to span the Golden Gate Strait. But through sheer determination and innovative thinking, engineers and workers pulled off one of the greatest feats of modern history.

So, buckle up because we’re diving deep into the obstacles faced during the construction of this legendary landmark. From battling harsh weather conditions to groundbreaking engineering solutions, this article will take you on a journey through the challenges of building the Golden Gate Bridge—and how they were conquered.

Read also:Hyungry Temporary The Ultimate Guide To Temporary Hunger Solutions

Table of Contents

- Early History and Vision

- Financial Challenges

- Environmental Hurdles

- Engineering Innovations

- Worker Safety and Risks

- Technical Difficulties

- Public Opposition

- Material Sourcing

- Construction Process

- Legacy and Impact

Early History and Vision

The idea of bridging the Golden Gate Strait dates back to the late 19th century, but it wasn’t until the 1920s that the vision became a realistic goal. The challenges of building the Golden Gate Bridge started long before construction began. It required a visionary leader like Joseph Strauss, the chief engineer, to bring the project to life.

Back then, San Francisco was booming, but its growth was limited by its geographical location. The only way to cross the strait was by ferry, which was time-consuming and inefficient. Strauss saw the potential of a suspension bridge connecting San Francisco to Marin County, and he made it his life’s mission to make it happen.

However, the journey wasn’t easy. Strauss faced skepticism from experts who believed the strait’s treacherous waters and strong winds made it impossible to build a bridge. But he didn’t give up. He assembled a team of brilliant engineers and architects, including Charles Alton Ellis and Irving Morrow, who would help turn his dream into reality.

Financial Challenges

Money talks, and in the case of the Golden Gate Bridge, it screamed. The challenges of building the Golden Gate Bridge included securing funding during one of the most challenging economic periods in history—the Great Depression. It’s hard to imagine raising $35 million (the estimated cost at the time) when banks were failing and unemployment was skyrocketing.

But Strauss and his team found a way. They convinced local governments and businesses to support the project, arguing that it would create jobs and boost the economy. In 1930, voters approved a bond measure to finance the bridge, but it wasn’t smooth sailing. Banks were hesitant to back the project, fearing it wouldn’t generate enough revenue.

Eventually, the Bank of America stepped in, providing the necessary funds. This was a huge relief, but the financial strain didn’t end there. Throughout construction, the team had to constantly manage budgets and find ways to cut costs without compromising quality.

Read also:Lakers Roster 2024 Your Ultimate Guide To The Upcoming Season

Cost Overruns and Budget Management

Even with the initial funding secured, cost overruns were a constant threat. Materials were expensive, labor costs were high, and unexpected expenses kept popping up. The team had to think creatively to keep the project within budget.

For example, they used a technique called “deflection theory” to reduce the amount of steel needed for the bridge’s towers. This not only saved money but also made the bridge more aesthetically pleasing. It’s a win-win situation when innovation meets budget constraints!

Environmental Hurdles

Nature wasn’t exactly welcoming to the construction crew. The challenges of building the Golden Gate Bridge included dealing with some of the harshest environmental conditions on the planet. The strait is notorious for its strong currents, foggy weather, and unpredictable winds.

Imagine working hundreds of feet above the water, battling 60-mile-per-hour winds and dense fog that can reduce visibility to near zero. It sounds like something out of an action movie, but this was the daily reality for workers on the bridge.

One of the biggest concerns was the depth of the water. At its deepest point, the strait is over 365 feet deep, making it difficult to anchor the bridge’s foundations. Engineers had to design a system that could withstand the immense pressure from the water and the forces of nature.

Fog and Wind: The Invisible Obstacles

Fog might seem harmless, but when you’re trying to align massive steel beams with precision, it becomes a major problem. Workers often had to rely on radio communication and carefully planned schedules to ensure everything was in place.

As for the wind, it was relentless. Engineers had to design the bridge to flex and sway without collapsing. This required extensive testing and calculations to ensure the structure could handle the forces exerted on it.

Engineering Innovations

When it comes to the challenges of building the Golden Gate Bridge, innovation was the key to success. The project pushed the boundaries of what was possible at the time, leading to groundbreaking advancements in engineering.

One of the most significant innovations was the use of “spider legs” during the construction of the anchorages. These temporary supports allowed workers to position the massive cables with precision. Another innovation was the development of a special paint designed to withstand the corrosive effects of saltwater and fog.

The bridge’s design also incorporated safety features that were ahead of their time. For example, the safety net stretched beneath the bridge during construction saved the lives of 19 workers, earning them the nickname “Halfway-to-Hell Club.”

Cable Spinning: The Heart of the Bridge

One of the most complex aspects of the construction was the spinning of the main cables. Each cable consists of thousands of individual wires, all carefully woven together to create a structure capable of supporting the bridge’s weight.

This process required meticulous planning and execution. Workers had to ensure that each wire was perfectly aligned and tensioned to prevent any weak points in the cable. It was a painstaking process, but it paid off in the end, resulting in one of the strongest suspension bridges in the world.

Worker Safety and Risks

Safety was a top priority, but it wasn’t always easy to ensure. The challenges of building the Golden Gate Bridge included protecting workers from the dangers of working at great heights and in extreme conditions.

Despite the safety net, 11 workers lost their lives during construction, most of them in a single tragic accident when a scaffolding fell through the net. This tragedy underscored the importance of ongoing safety measures and improvements.

Engineers and managers worked tirelessly to implement new safety protocols, such as requiring workers to wear hard hats and harnesses. These measures became standard practice in construction projects around the world, highlighting the bridge’s lasting impact on workplace safety.

The Halfway-to-Hell Club: A Testament to Courage

Let’s take a moment to honor the 19 workers who survived falls into the safety net. They were known as the “Halfway-to-Hell Club,” a testament to their courage and resilience. These men risked their lives every day to build a structure that would inspire generations.

Their stories remind us of the human cost of such monumental projects. Without their bravery, the Golden Gate Bridge might never have been completed.

Technical Difficulties

From designing the bridge’s foundations to aligning the cables, technical difficulties plagued the project from start to finish. The challenges of building the Golden Gate Bridge included solving complex engineering problems that had never been encountered before.

For example, engineers had to figure out how to transport massive steel beams across the strait without disrupting shipping traffic. They also had to ensure that the bridge’s towers were perfectly aligned, despite the fog and wind.

Each problem required a unique solution, and the team rose to the occasion every time. Their ability to adapt and innovate is a testament to their expertise and dedication.

Foundation Problems and Solutions

One of the biggest technical challenges was laying the foundations for the bridge’s towers. The depth of the water and the strength of the currents made it nearly impossible to anchor the structures securely.

Engineers came up with a clever solution: they used caissons, or hollow steel boxes, to create a stable base. These caissons were sunk into the seabed and filled with concrete, providing a solid foundation for the towers.

Public Opposition

Not everyone was thrilled about the idea of building the Golden Gate Bridge. Public opposition was one of the challenges of building the Golden Gate Bridge that couldn’t be ignored. Ferry operators, in particular, were vocal in their protests, fearing that the bridge would put them out of business.

Some residents were also concerned about the environmental impact of the project, worried that it would disrupt marine life and natural habitats. Engineers and planners had to work hard to address these concerns and win over skeptics.

In the end, the benefits of the bridge outweighed the drawbacks. It not only improved transportation but also became a symbol of hope and progress for the region.

Winning Over the Community

Engaging with the community was crucial to the project’s success. Engineers held public meetings and published reports to educate people about the bridge’s benefits. They also emphasized the economic opportunities it would create, such as new jobs and increased tourism.

These efforts paid off, as public opinion gradually shifted in favor of the bridge. By the time construction was complete, the Golden Gate Bridge had become a beloved icon of San Francisco.

Material Sourcing

Getting the right materials to the construction site was another challenge. The challenges of building the Golden Gate Bridge included sourcing high-quality steel and other materials from across the country.

Most of the steel came from Bethlehem Steel in Pennsylvania, transported by ship across the continent. This journey was fraught with risks, including the possibility of delays due to weather or shipping accidents.

Once the materials arrived, they had to be carefully inspected and tested to ensure they met the project’s stringent standards. Any defects could have catastrophic consequences, so quality control was a top priority.

Logistical Challenges and Solutions

Transporting materials across the strait was a logistical nightmare. Engineers had to coordinate with shipping companies and local authorities to ensure smooth delivery. They also had to develop systems for storing and organizing materials on-site.

Despite these challenges, the team managed to keep the project on schedule. Their ability to overcome logistical hurdles was a testament to their organizational skills and attention to detail.

Construction Process

From start to finish, the construction of the Golden Gate Bridge took over four years. The challenges of building the Golden Gate Bridge included managing a complex timeline and coordinating the efforts of thousands of workers.

Construction began in January 1933 with the laying of the foundation. Over the next few years, workers toiled day and night to complete the bridge, facing numerous obstacles along the way. By April 1937, the bridge was finally ready for its grand opening.

The dedication and hard work of everyone involved in the project made it possible to complete such an ambitious undertaking. It’s a testament to what humans can achieve when they come together with a common goal.

Key Milestones and Celebrations

Throughout the construction process, there were several key milestones that marked the progress of the project. For example, the completion of the main cables was a cause for celebration, as was the installation of the first section of the roadway.

When the bridge finally opened to the public, it was a day of jubilation for the entire region. People came from all over to witness this marvel of engineering and celebrate its completion.

Legacy and Impact

The challenges of building the Golden Gate Bridge may have been immense, but the results speak for themselves. Today, the bridge stands as a testament to human ingenuity and perseverance. It’s not just a functional structure; it’s an icon of San Francisco and a symbol of hope for people around the world